Laser cutting technologies has revolutionized many industries by providing precision and efficiency that standard methods wrestle to match. If you're taking into consideration diving into the entire world of laser reducing, It truly is vital to know how laser chopping devices work and why they're starting to be indispensable. Let us break down everything from the basics to your Highly developed capabilities of those equipment and investigate why they may be an ideal in shape for your requirements.

With the core of the technological know-how will be the laser cutter, a tool that utilizes a centered laser beam to cut or engrave components. Unlike other reducing procedures, a laser cutter directs a substantial-powered laser beam via a lens, which concentrates The sunshine right into a wonderful position. This permits for very exact cuts and intricate types on a variety of elements. Visualize using a laser to carve out specific styles over a bit of steel—It is really that kind of precision that makes laser cutters jump out.

Everything about Industrial Laser Cutting

Industrial laser slicing usually takes this idea to a bigger scale, exactly where high-run lasers are Utilized in producing environments to cut by means of thicker materials with incredible precision. For industries for instance automotive, aerospace, and construction, where by tolerances are tight and materials are tough, industrial laser chopping is a sport-changer. These units can manage huge sheets of steel and also other components with negligible squander and greatest precision.

Industrial laser slicing usually takes this idea to a bigger scale, exactly where high-run lasers are Utilized in producing environments to cut by means of thicker materials with incredible precision. For industries for instance automotive, aerospace, and construction, where by tolerances are tight and materials are tough, industrial laser chopping is a sport-changer. These units can manage huge sheets of steel and also other components with negligible squander and greatest precision.CNC laser slicing is another remarkable improvement In this particular area. CNC means Laptop or computer Numerical Manage, and it refers to the automated control of equipment tools utilizing pcs. By integrating CNC engineering with laser slicing, you obtain a equipment that not simply cuts but does so by using a degree of regularity and repeatability that manual procedures are not able to match. This is especially useful for initiatives necessitating a number of identical elements or complex styles.

Laser reducing engineering is repeatedly evolving, with new advancements strengthening effectiveness, pace, and flexibility. By way of example, modern laser chopping machines usually involves advanced software program that enables For additional elaborate styles and quicker processing times. With these improvements, it's less complicated than ever before to accomplish significant-top quality cuts and designs, whether or not you happen to be engaged on compact prototypes or significant-scale generation runs.

In regards to precision laser cutting, the ability to realize exact measurements and intricate aspects is unmatched. This is critical for industries where by just about every millimeter counts, like in electronics or wonderful jewelry. Laser cutters can tackle incredibly great aspects, producing them ideal for applications exactly where precision is paramount. If you've ever marveled with the high-quality specifics of a view or even the sensitive options of a circuit board, chances are a laser cutter was involved with its generation.

Sheet steel laser cutters are a particular variety of laser slicing products meant to manage flat sheets of steel. These equipment are ideal for cutting pieces for equipment, automotive factors, along with other metallic goods. The precision and pace of sheet metal laser cutters permit suppliers to make large-excellent parts effectively, reducing manufacturing time and fees.

The Buzz on Laser Cutting Services

Laser slicing services have also turn into greatly accessible, giving corporations entry to large-high-quality slicing with no require for in-household equipment. Several assistance suppliers offer you A selection of access here solutions, from basic cuts to intricate models, and might function with different materials, together with metals, plastics, and composites. This implies you could entry prime-notch laser slicing technological know-how with no the significant expense in equipment.

Laser slicing services have also turn into greatly accessible, giving corporations entry to large-high-quality slicing with no require for in-household equipment. Several assistance suppliers offer you A selection of access here solutions, from basic cuts to intricate models, and might function with different materials, together with metals, plastics, and composites. This implies you could entry prime-notch laser slicing technological know-how with no the significant expense in equipment.The Definitive Guide for Laser Cutting Technology

One of several key great things about laser chopping systems is their versatility. They're able to Slice as a result of a number of supplies, including metals, plastics, Wooden, and also fabrics. This helps make them very practical in many various industries, from vogue layout to manufacturing. No matter if You are looking to develop tailor made areas for an item or style and design intricate patterns for your bit of artwork, laser chopping units can tackle all of it.When it comes to operational performance, laser reducing devices can be a prime choice. They usually involve significantly less handbook intervention in comparison to other chopping techniques, leading to fewer errors and lessen labor expenditures. This automation also contributes to dependable excellent across production runs, that is very important for keeping specifications in industrial configurations.

Laser chopping know-how isn't just about cutting products; it's also about a chance to engrave or mark surfaces with precision. This is especially handy for creating in depth labels, serial quantities, or attractive patterns. Using a laser cutter, it is possible to reach superior-good quality engravings which can be equally resilient and aesthetically pleasing, making it a beneficial Device for both of those purposeful and decorative purposes.

The adaptability of laser chopping technologies means that it isn't limited to unique industries. From generating personalized signage to crafting intricate jewelry, the purposes are huge and different. This versatility is probably the explanation why laser slicing happens to be this sort of a popular decision across distinctive fields.

An additional advantage of laser reducing is its capability to produce complex shapes and types with no want for additional tooling. Common slicing techniques generally involve distinct equipment for various designs, but that has a laser cutter, you can easily adjust the look and make alterations about the fly. This functionality is particularly valuable for prototyping and tailor made perform, where adaptability is vital.

Laser chopping techniques also are recognized for their clean cuts and minimal product waste. The precision with the laser beam means that cuts tend to be incredibly slim, minimizing the level of excess substance that should view the article be trimmed away. This performance not just can help in minimizing costs but will also contributes to additional sustainable producing techniques by reducing waste.

For firms aiming to put money into laser slicing devices, it is vital to consider the particular desires of the operations. Aspects including the sorts of products you'll be cutting, the complexity of your respective patterns, and the amount of work will all impact the kind of laser cutter that best fits your prerequisites. Doing comprehensive research and consulting with industry experts can assist you make an educated choice.

The future of laser cutting engineering seems to be promising, with ongoing progress driving advancements in pace, precision, and flexibility. As technology carries on to evolve, we are able to count on much more impressive answers and apps to arise, creating laser slicing an all the more integral portion of manufacturing and design and style.

Facts About Laser Cutting Services Uncovered

In learn more summary, laser cutting machines and methods provide unparalleled precision, performance, and flexibility. Whether or not you are linked to industrial producing, personalized structure, or any discipline that needs correct cutting or engraving, laser reducing technologies has some thing to supply. By knowing the different elements of laser cutting, from products to providers, you can improved value its influence and likely for your own personal tasks.

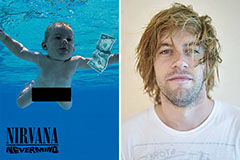

Spencer Elden Then & Now!

Spencer Elden Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now!